ASK A PROJECT MANAGER: STORMWATER CONTROL MEASURES

We sat down with Nate Lehigh, PE, who serves as the Project Manager for the Pennsylvania Department of Transportation (PennDOT) District 6's Stormwater Control Measures (SCMs) Asset Management Support Services task. He provides technical oversight for the inventory and inspection of the SCMs in District 6, provides remediation design and construction documents for failed SCMs, and researches and provides Pollutant Reduction Plans (PRP) and credit opportunities for the District.

Tell us a little bit about what the project is and who it benefits.

The goal of the project is to provide asset management and support services for PennDOT District 6 SCMs in order for PennDOT to remain compliant with their MS4 permit requirements. Our team has inventoried and inspected 415 SCMs across Bucks, Chester, Delaware, Montgomery, and Philadelphia Counties and has completed remediation design for over 30 SCMs.

What about the project highlights McCormick Taylor’s talents?

The project blends our team’s organizational skills, GIS capabilities, and experience designing and inspecting stormwater facilities throughout the mid-Atlantic region. We have been able to showcase our inventory management, inspection, and remediation design of stormwater facilities with this project, as we have with other clients previously. The high quality work we’ve done on the project is only possible because of our great team of inspectors and engineers.

What has the feedback been like from the community?

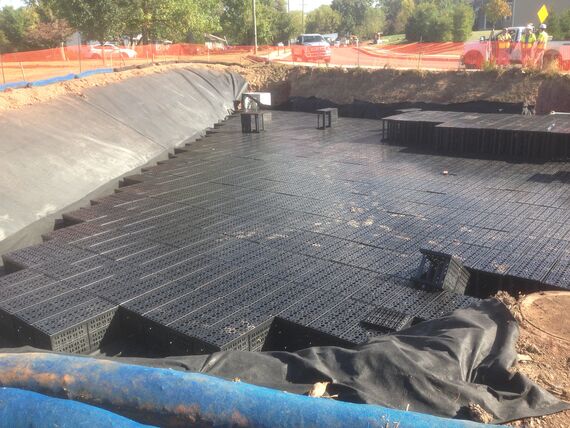

The majority of PennDOT’s SCMs are located adjacent to state roadways so they are mostly out of sight, out of mind to the general public. One example of positive feedback was at a failed rain garden located next to a housing development. Due to unintended ponding, mosquito issues, and overgrown and invasive vegetation, the community requested the site be converted to an underground facility. Once completed, the area was unrecognizable as an SCM to the untrained eye and still provided the same SWM benefits, which is exactly what the community wanted. See photos to the right.

Have you come across any challenges or concerns while working on this project?

Some of the SCMs we’ve inspected were designed and constructed before the current design guidelines were as refined as they are now. There have been several instances where an SCM is a hybrid of two standard types of SCMs, so we provide PennDOT a recommendation of how to best categorize the site in the inventory.

Another challenge has been finding SCM features during inspections that aren’t reflected on the plans. This is most often a result of design revisions made during construction that weren’t properly documented. It can be a challenging process to determine if the field change inhibits the functionality of the facility for the originally designed facility type.

Does the project have any unique aspects?

Yes. Some might say every project is a snowflake. The same applies to SCM facilities. The many design variants for the multiple types of SCMs, combined with natural or man-made forces that have occurred between construction and the time of inspection, make for unique findings. The most unique example was a dry detention basin with an impermeable liner under the surface to prevent infiltration into the Karst geography below. This site had high groundwater, and the subsurface water pressure had heaved the liner to the surface. Walking over this facility was like walking on a waterbed.

Can you touch on some of the key technical aspects of the project?

The most technical aspect of the project is the knowledge of the various SCM types and how each of them is supposed to function. The inspectors need to understand the functionality of each type of SCM in order to report items that are not in compliance. In addition to understanding the functionality of each type of SCM and being able to identify items that are out of compliance, the remediation designers need to also understand the cause of the issue in order to design a preventative repair to extend the life of the SCM for as long as possible.

What’s your favorite part of the project?

My favorite part of the project is being able to see all the different design nuances of the SCMs in the field and being able to take the best practices to our future designs. Learning from other people’s mistakes is always much more fun than learning from your own!

Are there any social, economic, or sustainable development aspects of the project?

As mentioned earlier, the main goal of the project is to identify SCMs in need of repair and remediate the issue. The remediation design is done to prevent the initial cause of the issue from happening again. Therefore, the state will save money on future maintenance costs while reducing the amount of total suspended solids and other pollutants that make it to the waterways. Helping to reduce pollutants upstream of our main waterways supports future habitats for aquatic vegetation and species.